Lean Six Sigma Methodology and Tools

Introduction to Lean Six Sigma

In today's competitive business landscape, organizations are continuously seeking methods to enhance their efficiency and effectiveness. Lean Six Sigma serves as a powerful approach to achieve this by combining the principles of Lean and Six Sigma methodologies. As a Lean Six Sigma trainer, I have had the privilege to assist organizations in creating awareness and training employees on these impactful strategies.

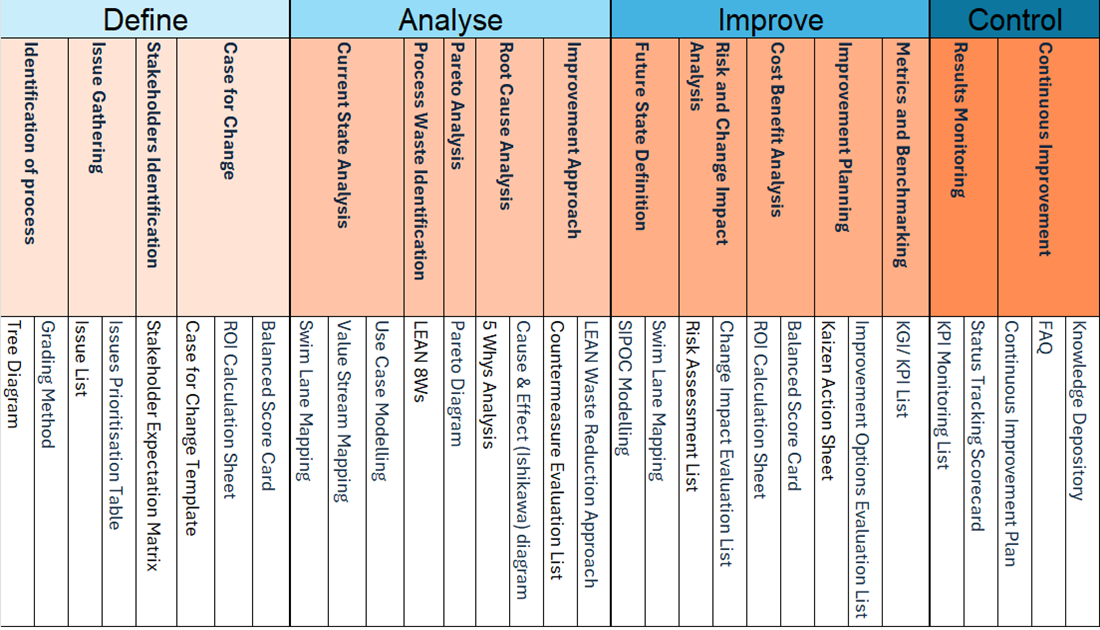

Understanding the Process: Define, Analyze, Improve, Control

At the core of Lean Six Sigma is a structured methodology that guides businesses through the Define, Analyze, Improve, and Control (DMAIC) phases. These stages provide a framework for organizations to visualize their processes better. By implementing tools such as the cause-and-effect diagram and the swim-lane diagram, I have helped the team to effectively identify key areas of inefficiency within their business processes.

Transforming Challenges into Opportunities

Once inefficiencies were pinpointed, I have helped to facilitate the translation of these problem areas into tangible improvement opportunities. Utilizing Lean Six Sigma tools like the improvement options evaluation list and the Kaizen action sheet, the team had systematically address challenges.

Igniting a Culture of Continuous Improvement

Implementing Lean Six Sigma had helped the organization to foster a culture of continuous improvement. By training employees on these principles, they gain valuable insights into optimizing performance and enhancing operational efficiency. As I had helped them to continue to embrace these methodologies, they had shifted toward a more data-driven approach, ensuring sustainable growth and advancement. The journey toward continuous improvement is not only beneficial for operations but also helped in fostering of a motivated and engaged workforce.