Lean Concept – 7 Wastes

About Course

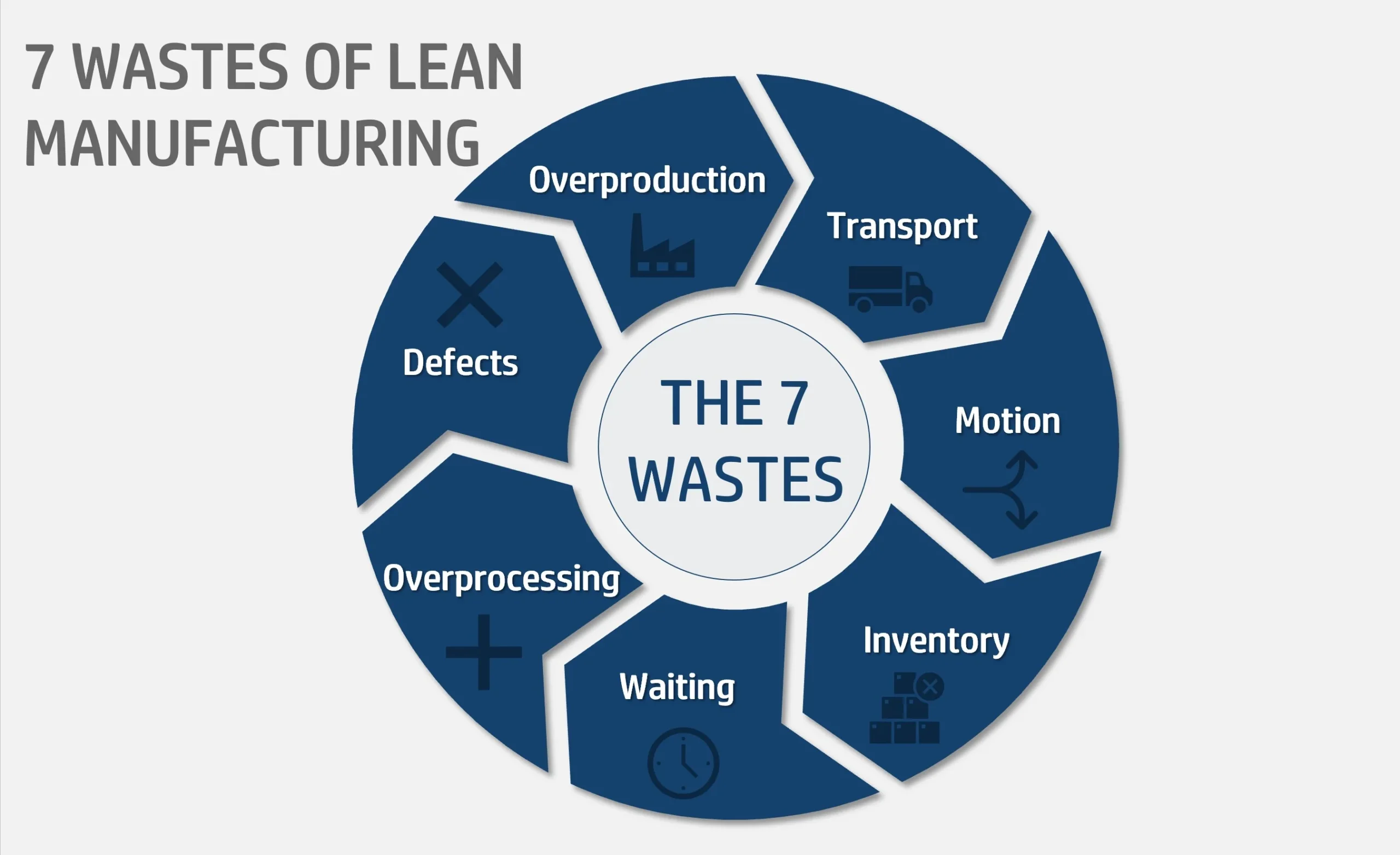

Muda is a Japanese word that translates to waste. The concept that muda must be eliminated in a process is a driving concept of the Toyota Production System and Lean manufacturing. Muda is a non-value-added task (NVA) within a process.

Waste costs money because it is unnecessary time, labor, or material in the process. Generally, waste is something that is used in the process that isn’t required for satisfactory outcome. According to chief engineer for Toyota, there are seven muda, or resources that are commonly misused and mismanaged: overproduction, conveyance, over processing, correction, inventory, motion, and waiting.

Course Content

Lean Concept – The Seven Muda (Wastes)

Student Ratings & Reviews

No Review Yet