Introduction to Sales Order Challenges

I was engaged in a project aimed at improving the sales order value chain for a well-known global brand. Despite their extensive presence, the brand faced unique challenges stemming from their multi-channel sales strategy.

The Issues with Order Collection

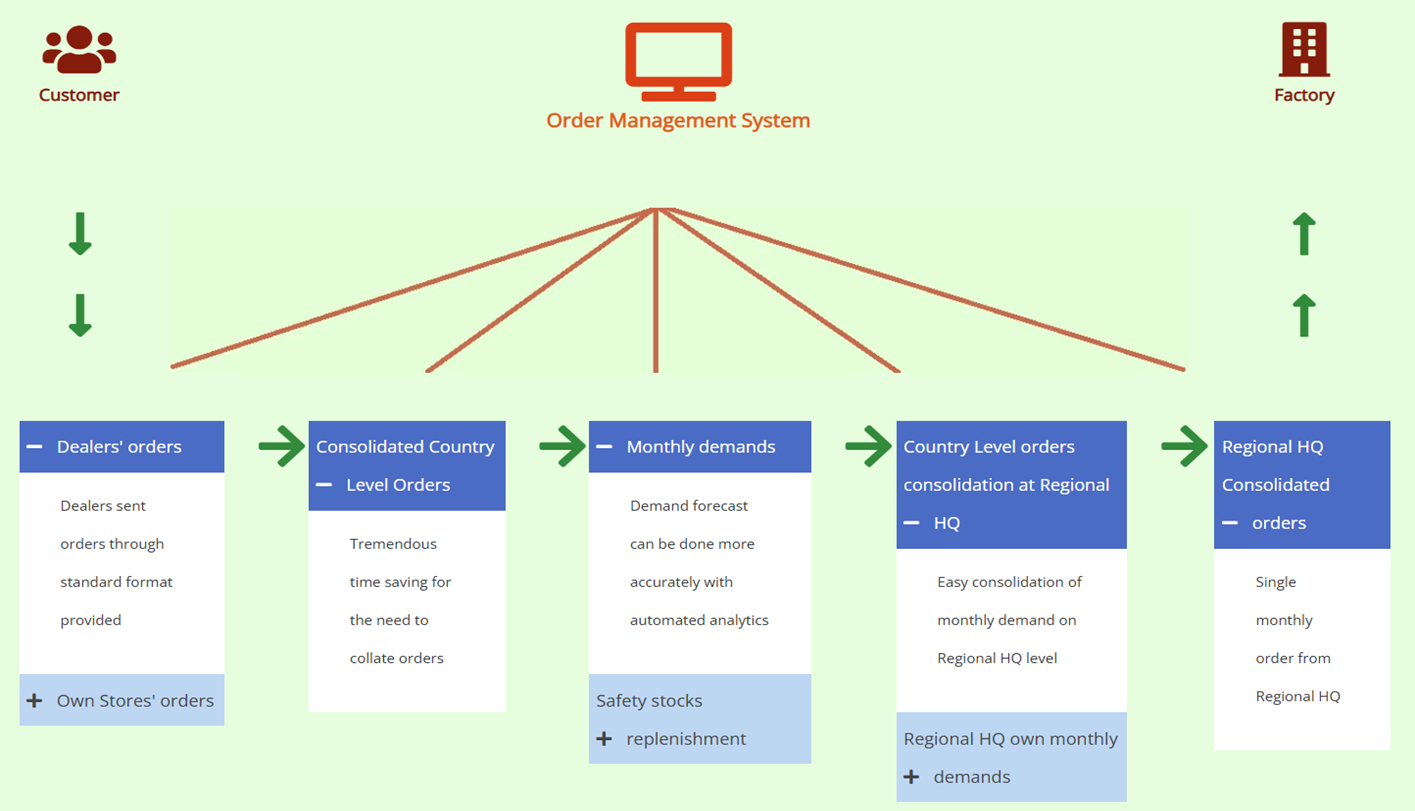

The global brand sells through both dealers and their own stores, which introduces complexity into their sales order process. Variability in the formats and frequency of sales order collection from these stores resulted in significant delays. The disjointed approach required additional time to collate the orders into a single monthly submission to the factory. This inefficiency led to missed opportunities and customer dissatisfaction.

The Lack of Economies of Scale

Another key issue identified was the lack of economies of scale due to individual country operations sending their orders directly to the factory. Without a consolidated order approach, the brand missed out on potential cost savings and streamlined operations.

Improvement through integrated Order Management System

Implementing an advanced order management system has significantly enhanced the sales order value chain. This innovation allows for a streamlined process, ensuring that all entities involved in the whole value chain are linked and integrated; and sharing of information and resources are enabled.

Standardized Order Submission

One of the key improvements is the introduction of a standard format for dealers to submit their monthly orders. With this protocol in place, it allows for uniformity and reduces the chances of errors.

For the brand's own retail outlets, orders are now captured directly through the integrated system. This capability not only simplifies the ordering process but also enhances visibility into stock levels and sales trends.

Benefits of Consolidated Orders

One of the most notable advantages of the new order management system is its ability to facilitate the economic scale of consolidated orders. By gathering and processing orders from various country headquarters, at regional HQ level a larger, more cost-effective shipments can be arranged with manufacturing facilities. This not only reduces shipping costs but also optimizes resource allocation throughout the supply chain.

Enhanced Demand Forecasting and Safety Stock Planning

With automated analytics equipped with order management system, Demand Forecast was able to be done more accurately.

Furthermore, the system enables consolidated safety stock planning among different country headquarters, ensuring that businesses are well-prepared to meet fluctuations in demand without overstocking.